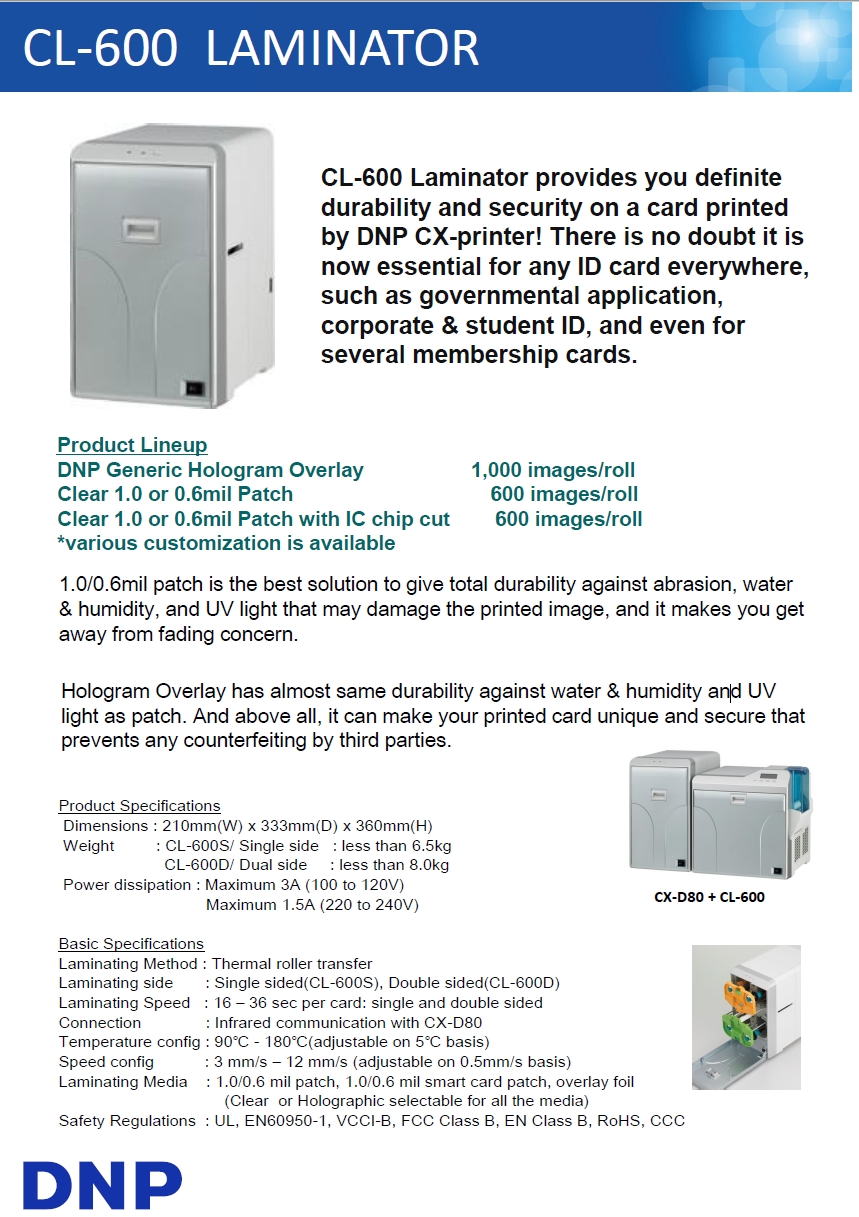

| Laminating method | Thermal roller transfer |

|---|---|

| Laminating side | Single sided (CL-600S), Double sided (CL-600D) |

| Laminating speed | 16 – 36 sec per card : single, and double sided |

| Connection | Infrared communication with CX-D80 |

| Temperature config | 90℃ – 180℃ (adjustable on 5℃ basis) |

| Speed config | 3 mm/s - 12 mm/s (adjustable on 0.5 mm/s basis) |

| Dimension | W210 x D333 x H360 (mm) |

| Weight | CL-600S: 8.5kg CL-600D: 9.5kg |

| Power Supply | Maximum 3A (100 to 120V), Maximum 1.5A (220 to 240V) |

| Operating Environment | 15℃ – 30℃, 35% – 70% non condensing humidity |

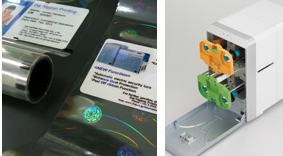

| Laminating media | 1.0/0.6mil patch, 1.0/0.6mil smart card patch, overlay foil |

| (Clear or holographic selectable for all the media) |

DNP WEBSITE: https://dnp.co.jp/international/cardprinter/products/cl_600/

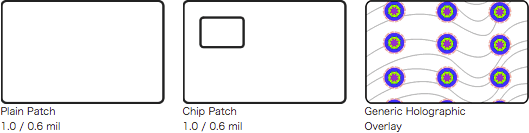

we are offering mainly two types of media: patch film and overlay foil.

1.0/0.6 mil patch film is the best solution to give all-round durability against abrasion, water & humidity, and UV light that may damage and deteriorate the printed image.

By adding an arbitrary hologram on a patch by customization, it is possible to make completely unique and secure card in terms of anti-counterfeit as well as physical protection.

Overlay foil has almost same durability against water & humidity and UV light as patch.

Little durability against abrasion, but it is possible to transfer the hologram on the whole area of card unlike patch film(2mm space around) and best suited for card decoration.

DNP has one generic hologram design for overlay, and surely possible to make your own hologram design for it.

| Product name | Product no. | Number of images |

|---|---|---|

| Clear full area 1.0 mil patch | CY-R10FC-60 | 600 images/roll |

| Clear full area 0.6 mil patch | CY-R06FC-60 | 600 images/roll |

| Clear smart card cut 1.0 mil patch | CY-R10SC-60 | 600 images/roll |

| Clear smart card cut 0.6 mil patch | CY-R06SC-60 | 600 images/roll |

| DNP Generic hologram overlay foil | CY-R00RD-100 | 1,000 images/roll |

*Custom design hologram patch/overlay is available.